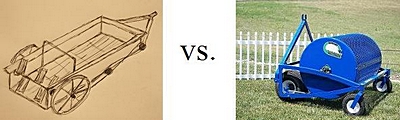

Traditional "Box-Type" Spreader |

The "Rotary" Spreader |

- Damage may occur if manure is too wet and/or heavy

|

- ROTATING DRUM makes manure weight work FOR you! (70% moisture or less is best)

|

- Stuck or wedged manure stops all spreading

|

|

|

- NO chains or cables to break

|

|

- Structural steel expanded metal drum powder coated for corrosion resistance

|

|

|

- Pasture unusable until waste has dissipated (sometimes taking a year or more)

|

- Shredded manure dissiptes within 2 weeks of spreading, allowing horses to return to the pasture MUCH soon.

|

- Discing or dragging fields is often needed

|

- Manure already shredded. No need to disc or drag.

|

- Large chunks fly out creating fly breeding hotspots

|

- Shredded manure dries quickly, virtually eliminating fly-breeding potential.

|

- Hay, long grasses, or twine may jam blades and break chains

|

- Uneaten hay collection system prevents clogging or jamming

|

- Heavy tongue weight when filled with manure. Weight makes it difficult to move and hitch up

|

- Weight balanced in four-wheeled frame keeps weight off of movable hitch

|

- Turning and spreading is virtually impossible due to one tire driving the blades and the other tire dragging the manure to the blades

|

- Tires have one job only: turning the rotating drum. This insures a nice even spread of manure, even in the tightest of corners. (see below)

|

|